Simesys, a software publisher of inspection and maintenance applications for the industry, announces the launch of Evolis Integrity V3, the new version of its software suite dedicated to the inspection of complex industrial infrastructures.

Launched in March 2021 and already adopted by major players in the Oil & Gas sector, Evolis Integrity responds to challenges common to many industrial sectors, by making it possible to optimize on-site intervention times, while standardizing and making inspection reports more reliable.

Covering all stages of the inspection cycle, the Evolis Integrity software suite is made up of:

- a back-office application, Evolis Integrity Web, that allows to manage data of the inspection sites, to prepare and export inspection files (« Workorders »), to process data following inspections and to edit standard reports ;

- and a tablet application, Evolis Integrity Tab, allowing the inspector to declare anomalies (« Damages ») and locate them precisely on inspection schematics, input measuring points, take pictures and attach them to the intervention report on the fly, and complete the intervention report.

Evolis Integrity 3: new features that strengthen the user experience

A major functional contribution: the 3D overview of the inspection

In version 3, Evolis Integrity offers an overview of the inspection in 3D (in addition to the 2D view, which is still available). On his tablet, via the Evolis Integrity Tab application, the inspector can thus visualize in 3D the equipment to be inspected, move the 3D object in three dimensions (either by multi-touch or with a stylus), then select it to inspect it. In the 3D view, the color of each item of equipment differs depending on whether its inspection is to be carried out, in progress or completed.

Real-time calculation of the corrosion rate and the service life of the equipment

All equipment is associated with an indicator which is updated after each inspection. This « Integrity status » provides precise visibility into the state of health of the equipment thanks to three data calculated from all the readings of measuring points and anomalies: the corrosion rate, the service life and a level of qualitative condition.

This visibility of the health of an equipment facilitates and optimizes the planning of inspections (predictive maintenance).

A greater variety of categories of measuring points and « damages »

To refine the results of the inspections carried out, the measuring points and the anomalies have been enriched with several types and categories. For example, anomalies can now be of the « quantitative » or « qualitative » type.

Also, the user experience has been improved when creating an anomaly and a measurement point with the presence of input fields and the choices in the drop-down lists depending on the types and categories selected.

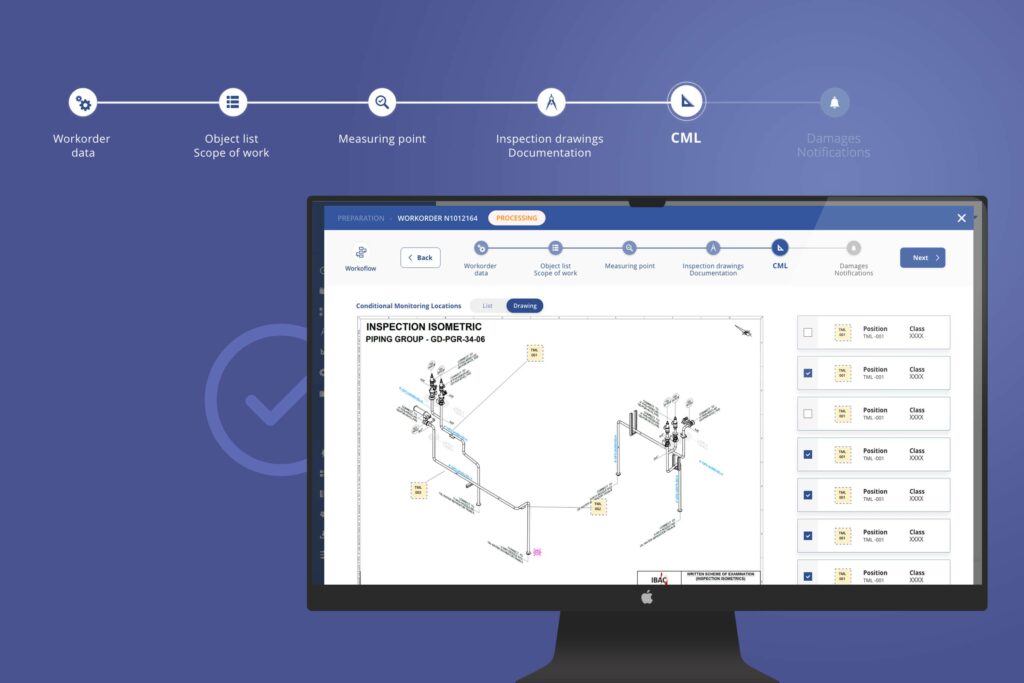

Advanced management of Workorders for standardized reports

In order to guide the user optimally, with Evolis Integrity 3, both the preparation and the reporting of an inspection file are carried out in successive and orderly stages, the passage to the next stage being conditioned by validation and control of the information entered.

Would you like to know more about our solutions?

Let’s talk over a coffee!